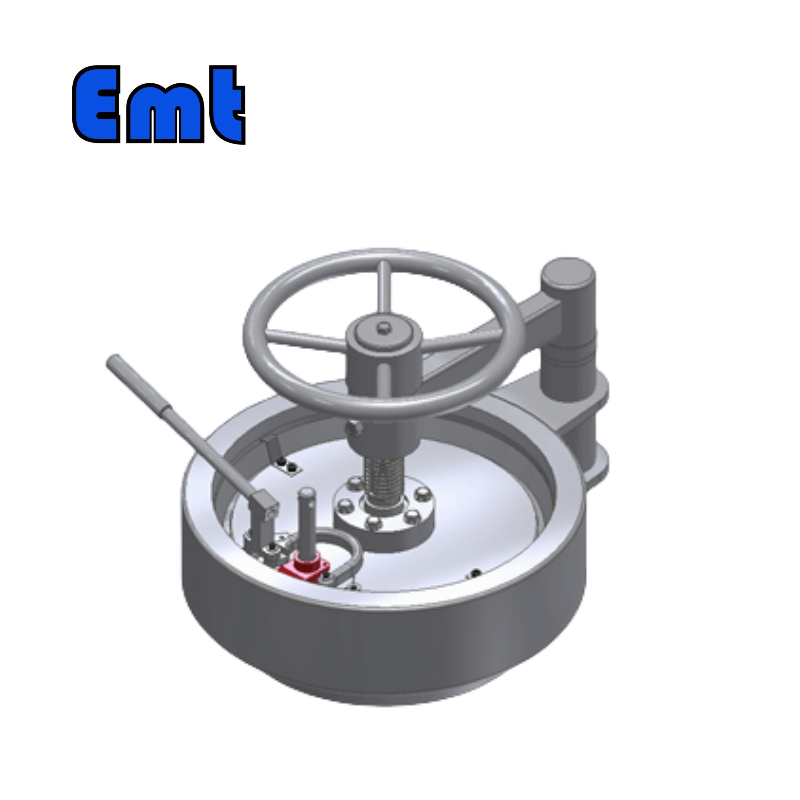

Description

Locking Band Closure | ||||

Design Pressure | 1.6MPa-30MPa | |||

Corrsoion Allowance | 2mm | |||

Seismic Fortification Intensity | 7 Degrees | |||

Work Medium | Oil, Natural gas, Water and ore pulp, etc. | |||

Opening Time | Within 60s less than 200N | |||

Opening Type | Vertical or Horizontal | |||

Key Attributes

Built-in Safety Mechanisms

Safety is a fundamental aspect in the engineering and production of the Locking Band Closure. It features a manually activated pressure warning screw that ensures the door remains locked until the vessel’s internal pressure is completely discharged. Further safety enhancements like mechanical key interlocks can be added and linked to control valve operations.

For optimal safety, the lock band is always in sight, complying with design code prerequisites and providing visual assurance to the operator that the door is firmly secured.

Door Pivoting

The door of the Locking Band Closure, designed for horizontal usage, is dual-pivoted with hinges containing self-lubricating bearings. The bolted assembly allows for adjustments for wear and can be customized for either left or right swing. A davit is provided for vertical installations, enabling the closure door to be lifted and moved clear of the hub. Then for diameters over 30″, the davit is replaced with lifting eyebolts to raise the door out of the way.

Seal Material

The standard seal material is 80° shore hardness Nitrile. Other available materials include Viton, HNBR, and explosive decompression-resistant grades. Depending on the type of elastomer used, the temperature range varies from -45°C to +210°C.

Hydrostatic Testing

While typically included as part of the final vessel test, a distinct closure hydrotest can be provided as an optional extra.

Distinctive Seal with Built-in Anti-Extrusion Spring

The custom-designed servo-acting lip seal becomes active at zero pressure, providing a completely airtight seal. The seal is located in the door, away from the work area, ensuring its durability and protection. It’s simple to install without the need for tools. The single-piece moulding, available in a variety of elastomers, includes a stainless steel spring to prevent extrusion and offer full vacuum functionality.

Materials

We offer forged steel hubs with either forged or plate doors that comply with all global material standards. Materials adhering to the NACE Standard MR-01-75 / ISO 15156 are also available.

Certified Design

Standard models adhere to ASME VIII Div.1. The designs can also meet the specifications of other pressure vessel codes, such as ASME VIII Div. 2 and PD5500. As an option, we can provide an ASME Code Stamp with a U-2A partial data report. Code stamping affirms that an authorized ASME Inspector has conducted a workshop inspection of the closure and its materials.

Compliance with European Pressure Equipment Directive (97/23/EC)

The following options are available:

Submit a technical file to the vessel fabricator for inclusion in the CE Marking of the vessel.

About Us

We provide customers with high-quality quick-opening blind plates, which are made of high-quality raw materials. Quick Opening Blind Panel Manufacturer These locking Band Closure panels,so we can customize them as per our customers’ requirements. These Locking Band Closure also have great durability and quality. Our Locking Band Closure can achieve preferential prices in the same industry.

Our lock-ring quick-open blind plates provide quick opening and closing of receiving and receiving bulbs on horizontal or vertical pipes. Lock ring quick opening blinds are to open any special tool quickly, usually within a minute.

Our advantages: quick opening closure manufacturer can open and close in a short time, durable, safe, reliable, customizable design

Quick opening closure manufacturer’s quick opening blind plate standards:

- “Technical Specifications for Quick Switch Blind Plate” SY/T 0556

- “Standard Pressure Vessel Safety Technical Supervision Specifications” TSG R0004

- “Pressure Vessel” GB150.1~4

- Quick-opening blind plate manufacturer “Pressure Vessel Welding Regulations” (NB/T47015)

- “Carbon steel and low-alloy steel forgings for pressure equipment” NB/T4708

- “Low alloy steel forgings for low-temperature pressure equipment” NB/T4709

- “Stainless steel and heat-resistant steel forgings for pressure equipment” NB/T 47010

- “Mechanical properties test of welded specimens of pressure-bearing equipment products” (NB/T47016)

Our Service

Firstly, many kinds of quick opening closure with different type to meet difference requirements.

Secondly, the fastest feedback!

Then, the fastest delivery time.

At last, 24 hours,7 days online.

Reviews

There are no reviews yet.